What Is Induction Lighting & How It Works

What Is Induction Lighting and How Does It Work?

Lighting has gone through several major overalls since Edison invented the light bulb. From incandescent to fluorescent, metal halide, LED, and many other technologies. Among all of them, induction lighting is a hidden gem that’s highly efficient and reliable, yet not that well-known.

Lighting has gone through several major overalls since Edison invented the light bulb. From incandescent to fluorescent, metal halide, LED, and many other technologies. Among all of them, induction lighting is a hidden gem that’s highly efficient and reliable, yet not that well-known.

Induction lighting is a fluorescent lighting technology that uses electromagnetic energy to start a chain reaction that causes phosphors to produce light. Unlike typical fluorescent lighting, induction lighting has no filament or electrodes, is more efficient, and lasts significantly longer.

The reliability, efficiency, and light-quality make induction lighting a perfect replacement for many types of high-watt lighting replacements, including fluorescent, metal halide, high-pressure sodium, and other forms of HID lighting.

What is the difference between induction lamps and fluorescent lamps?

Induction lamps create light much in the same way as does a fluorescent bulb. With both fluorescent tubes and induction lamps, mercury particles suspended in inert gas are excited. These particles in turn activate phosphors to produce visible light (more on this below). The main difference between induction and fluorescent bulbs is how the mercury particles are excited.

Fluorescent bulbs have an electrode or a filament to energize the mercury particles. Just like in incandescent bulbs, these filaments burn out over time. The filaments typically last about 10,000 hours, plus or minus a few thousand.

Induction bulbs, on the other hand, use an extremely durable inductor to energize the gas. Unlike filaments, these inductors typically don’t burn out. Other fail-points in the lamp may die after 30,000 – 50,000 hours. ILF’s industrial-grade induction lamps are among the best, rated for 100,000 hours.

How does an induction lamp work?

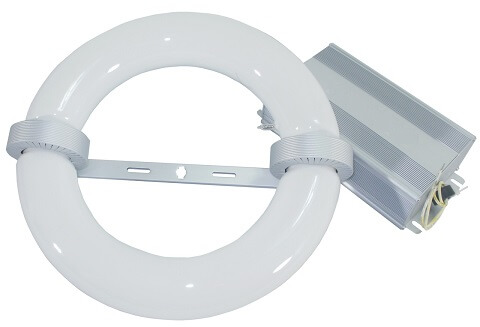

There are three main parts of an induction lamp. These are:

- The ballast

- The electromagnetic inductor

- The fluorescent bulb

Let’s take a look at how each of these three components function…

How the induction ballast works

Sometimes the ballast is contained in the bulb itself. These are called self-ballasted lamps. On higher wattage lamps and light fixtures, the ballast will be external to the bulb and attached to the induction light fixture. The electromagnetic inductor will always be packaged with the bulb.

Sometimes the ballast is contained in the bulb itself. These are called self-ballasted lamps. On higher wattage lamps and light fixtures, the ballast will be external to the bulb and attached to the induction light fixture. The electromagnetic inductor will always be packaged with the bulb.

The induction lamp ballast is a frequency generator. It takes the source electricity and converts it to a higher frequency that will excite the gases in the fluorescent tube. This frequency is typically 210 – 250 kHz. It will also provide an initial voltage boost to “kick-start” the reaction.

For induction lighting, the ballast is typically what wears out first. Still, our induction ballasts last an incredible 100,000 hours. That's over a decade of service for 12 hours a day every day.

How does the electromagnetic inductor work

The next part of the lamp is the electromagnetic inductor. This is similar to the magnets we made back in high school by wrapping a copper wire around a nail – only better. It’s high-powered and heavy-duty to produce more magnetic flux (magnetic energy).

It is donut-shaped to wrap around the fluorescent bulb. The magnetic flux produced will be focused in the middle of the donut, where the induction bulb is. The magnetic field will pass through the bulb and start the chain reaction.

How the fluorescent bulb lights up

The third element is the fluorescent bulb. Inside the bulb, mercury particles are suspended in an inert gas such as krypton or argon. As the magnetic field passes through the gas, the particles are excited and emit ultraviolet, or UV light. This high-energy UV is quickly transformed when it hits a special coating…

The third element is the fluorescent bulb. Inside the bulb, mercury particles are suspended in an inert gas such as krypton or argon. As the magnetic field passes through the gas, the particles are excited and emit ultraviolet, or UV light. This high-energy UV is quickly transformed when it hits a special coating…

The inside of the bulb is coated with phosphor. This phosphor absorbs the UV light and emits visible light. By combining blue, green, and red phosphors, the light emitted is white.

This white can be tuned to any desired color temperature, or kelvin scale. This is also called the “warmth” of the bulb. With the right mix in the phosphor coating, it can be 3000K, 4000K, 5000K, 6000K, or whatever you need it to be. While we sell 3000K to 6000K induction bulbs, we can also make them to your specific color temp needs.

Induction lights as an HID replacement

For most applications, the days of HID lights are numbered. They simply don’t hold much of any advantages over induction and LED lighting. Not in efficiency, light quality, longevity, nor cost.

Induction lighting technology holds a valuable place in commercial lighting. Induction lamps are a great alternative as a high-efficiency, low-maintenance lighting technology.

Take a look at our in-depth discussion about the pros and cons of induction lighting.